Services

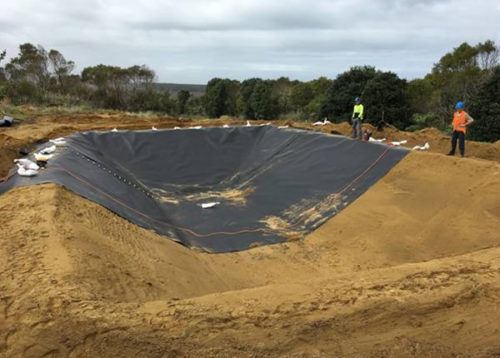

Pond & Dam Lining

HDPE lining systems are custom-made and tested on site to suit any shape or profile required suitable for:

HDPE lining systems are custom-made and tested on site to suit any shape or profile required suitable for:

- Landfills

- Total Water Containment

- Erosion Control

- Water Management

- Agricultural Dams and Waterways

- Effluent Ponds

- Environmental Protection

- Floating Covers

- Irrigation

- Chemical Containment

- Forest Fire Protection Dams

- Decorative and Ornamental Pond

Concrete Water Tank Lining

Utilising a blue or white HDPE liner, we can repair you leaking concrete tank by installing the liner inside your existing tank. The liner is measured to the shape and size of your tank then rolled up and then welded up inside your tank. The top of the liner is fixed using an aluminum flat bar and fixings as well as around pipe in and outlets.

Utilising a blue or white HDPE liner, we can repair you leaking concrete tank by installing the liner inside your existing tank. The liner is measured to the shape and size of your tank then rolled up and then welded up inside your tank. The top of the liner is fixed using an aluminum flat bar and fixings as well as around pipe in and outlets.

This is a cost-effective way to retaining your existing tank without the need for a replacement tank and installation of new plumbing. Some tanks may require new outlets to be fitted.

Concrete lined tanks also have the added benefit of keeping your water cool more so than new plastic water tanks and is drink water safe.

Note: This service is only provided in the Northland region as its not cost effective for the client outside of this region.

Vapour & Gas Barriers

Areas of construction where the ground is contaminated venting tubes and HDPE Liner is installed before casting of the concrete ground slab. This creates a barrier for any gasses or vapours from entering the structure.

Areas of construction where the ground is contaminated venting tubes and HDPE Liner is installed before casting of the concrete ground slab. This creates a barrier for any gasses or vapours from entering the structure.

Polyblocks (Lightweight fill)

Polyblock are polystyrene blocks fully incapsulated with HDPE liner for protection against outside elements such as petrol fuels. Depending on application these can be made either on or off site and transported. Polyblocks are a effective lightweight fill in areas were normal ground soils are unable to be compacted.

Polyblock are polystyrene blocks fully incapsulated with HDPE liner for protection against outside elements such as petrol fuels. Depending on application these can be made either on or off site and transported. Polyblocks are a effective lightweight fill in areas were normal ground soils are unable to be compacted.

Pipe Penetration

In area where a pipe need to pass through the HDPE liner, a pipe boot or top hat is fabricated out of HDPE liner. Fabricated, installed and tested on site to suit a variety of sizes and are sealed to pipes utilizing a mechanical fixing, suitable sealants and stainless-steel bands. This is a cost-effective method of sealing liner to any inlet/outlet pipe penetrations through the liner.

In area where a pipe need to pass through the HDPE liner, a pipe boot or top hat is fabricated out of HDPE liner. Fabricated, installed and tested on site to suit a variety of sizes and are sealed to pipes utilizing a mechanical fixing, suitable sealants and stainless-steel bands. This is a cost-effective method of sealing liner to any inlet/outlet pipe penetrations through the liner.

Liner Terminations

In areas where the liner finishes there a number of different methods can be applied. These consisted of Anchor trenches, Stainless Steel Battening or Polylock Welding.

In areas where the liner finishes there a number of different methods can be applied. These consisted of Anchor trenches, Stainless Steel Battening or Polylock Welding.

Anchor trenches are traditionally used for Ponds & Dams were the edge of the liner is buried in the ground. This also prevents the liner from slipping down steep slopes.

Stainless Steel Battening uses a combination of stainless steel bar, stainless steel bolts and recommended sealant for attaching liners to existing concrete structures. This creates a watertight seal between concrete and liner. This is a proven method of mechanical attachment of liners

Stainless Steel Battening uses a combination of stainless steel bar, stainless steel bolts and recommended sealant for attaching liners to existing concrete structures. This creates a watertight seal between concrete and liner. This is a proven method of mechanical attachment of liners

Polylock Welding is simply the liner welded to the polylock strips that have been cast into the concrete creating a waterproof seal or in area where a anchor trench is not possible to secure the liner.

Polylock Welding is simply the liner welded to the polylock strips that have been cast into the concrete creating a waterproof seal or in area where a anchor trench is not possible to secure the liner.